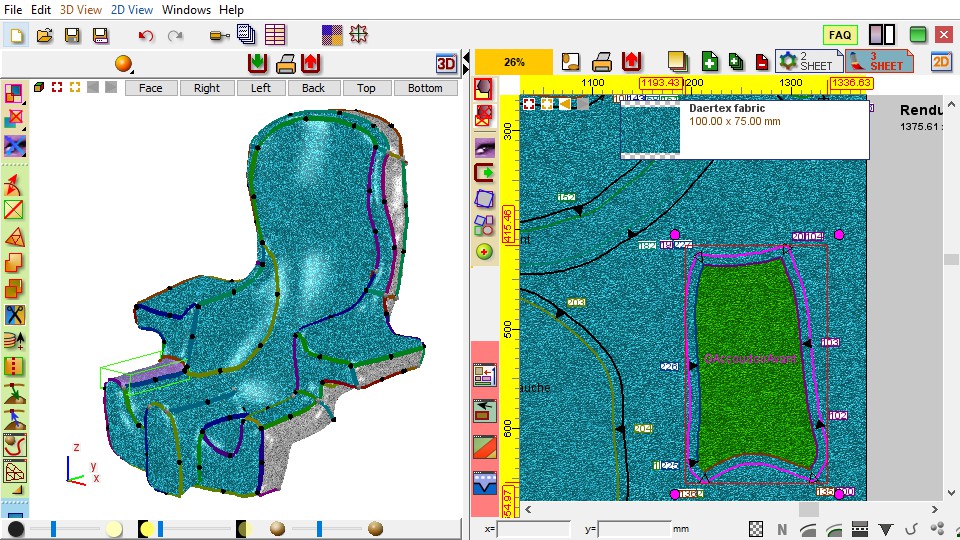

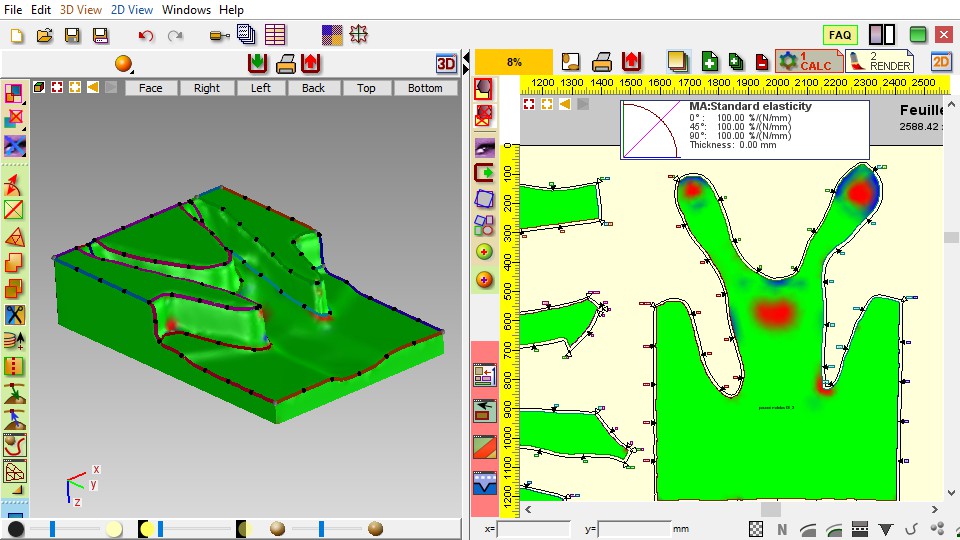

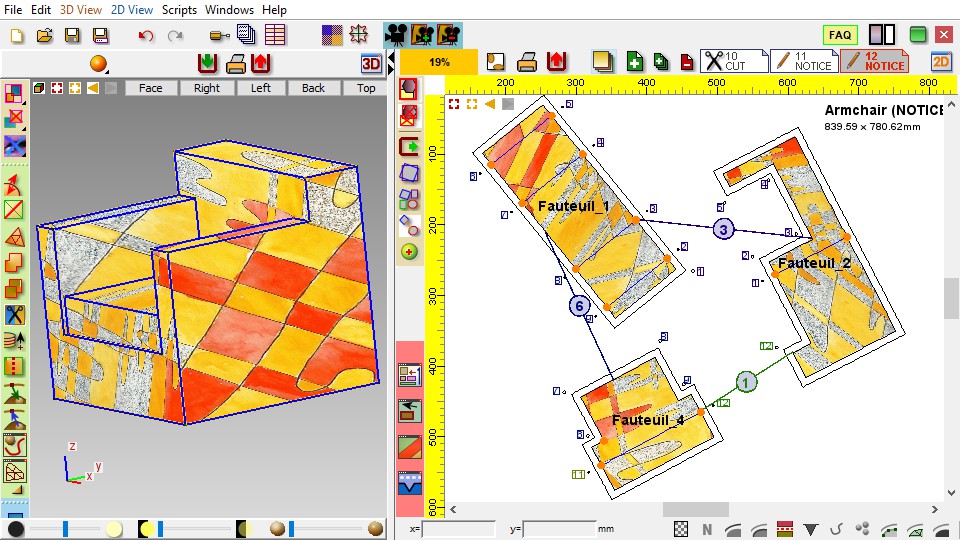

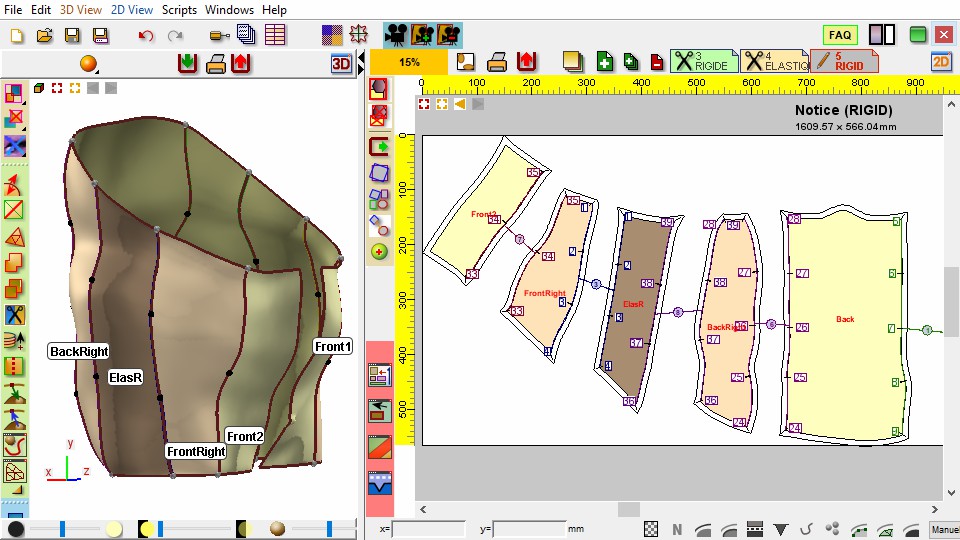

Seats

The seat coverings are at the origin of the Wrapstyler software. Whether for seats upholstered with traditional techniques or injected foam technology (called in-situ) or finally for seat covers, Wrapstyler is the ideal companion for the craftsman, the SME or the large industrial group.

Thanks to the features seams (cutting), flaps (seam allowances), notching, grain lines, Wrapstyler makes it possible to achieve incomparable levels of quality and profitability.

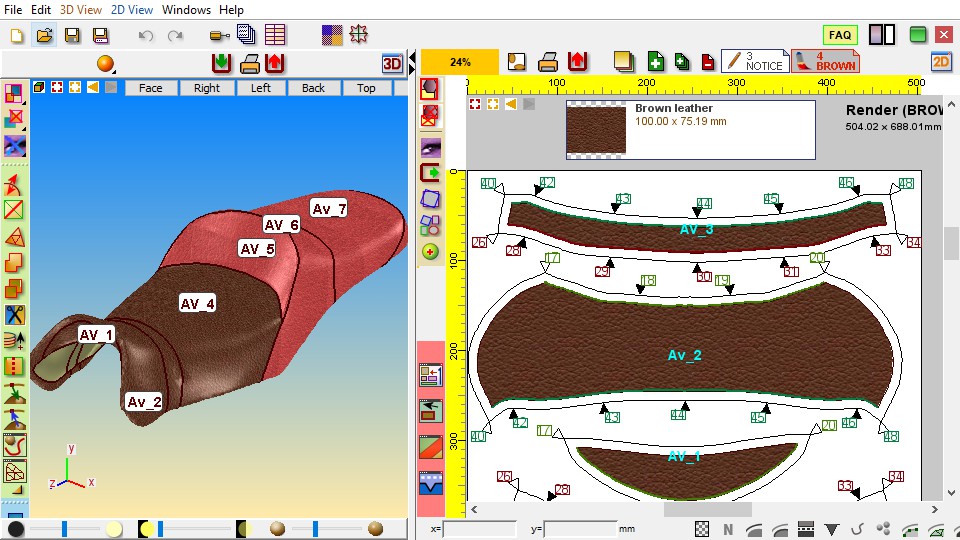

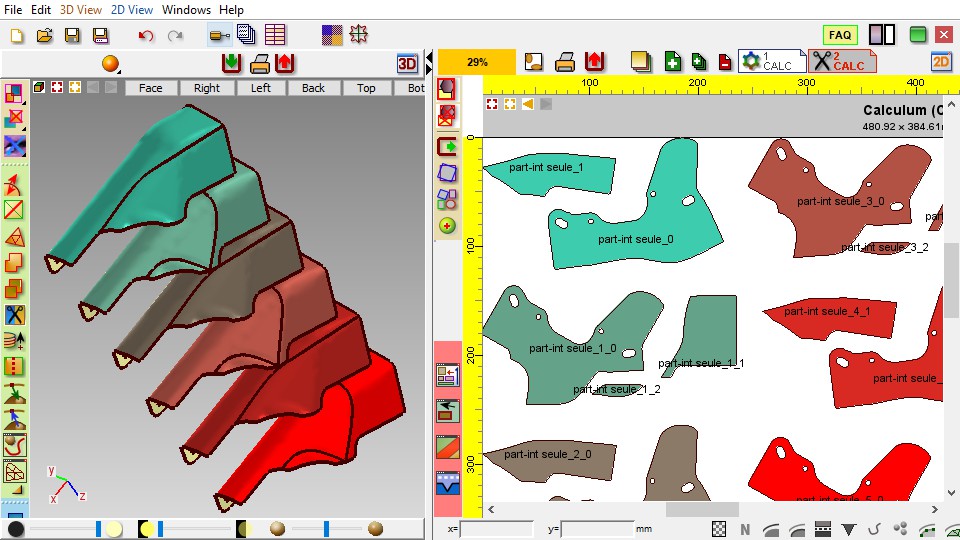

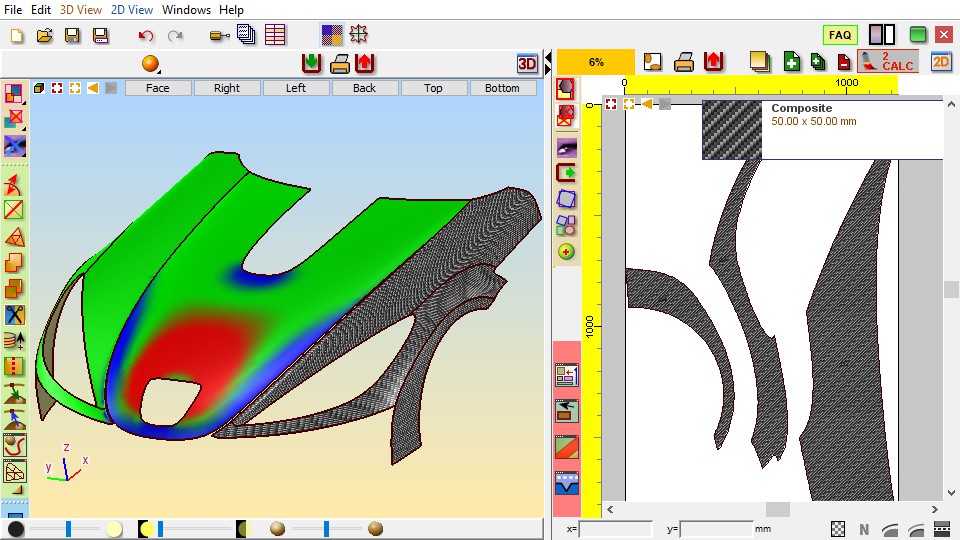

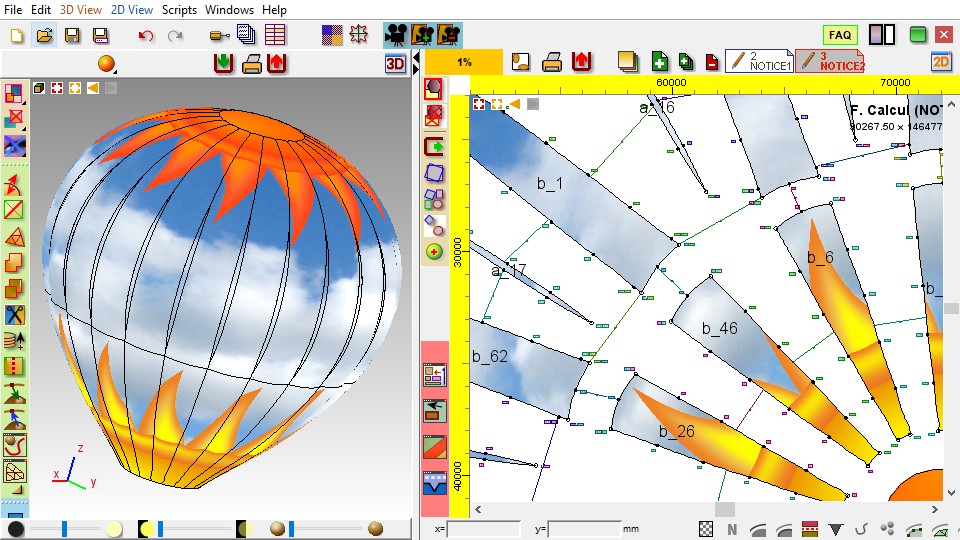

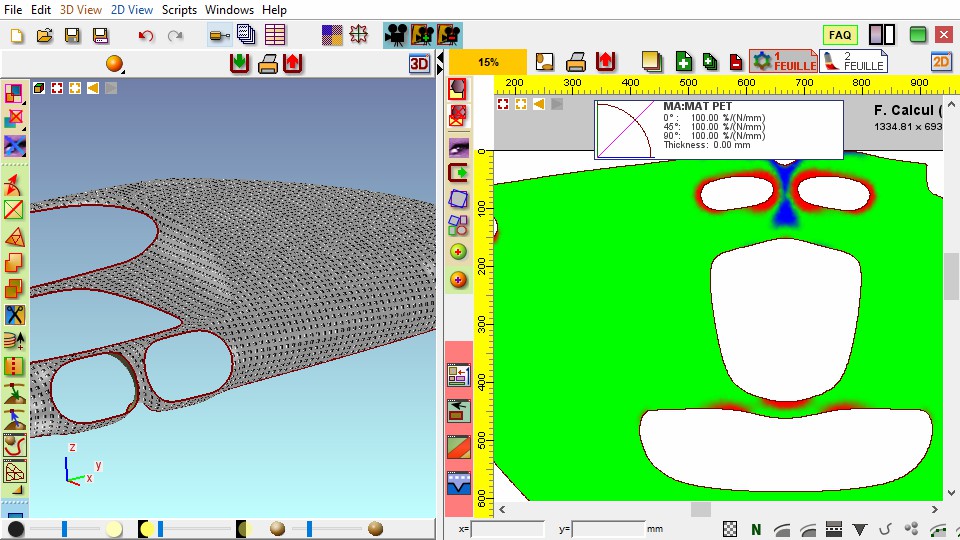

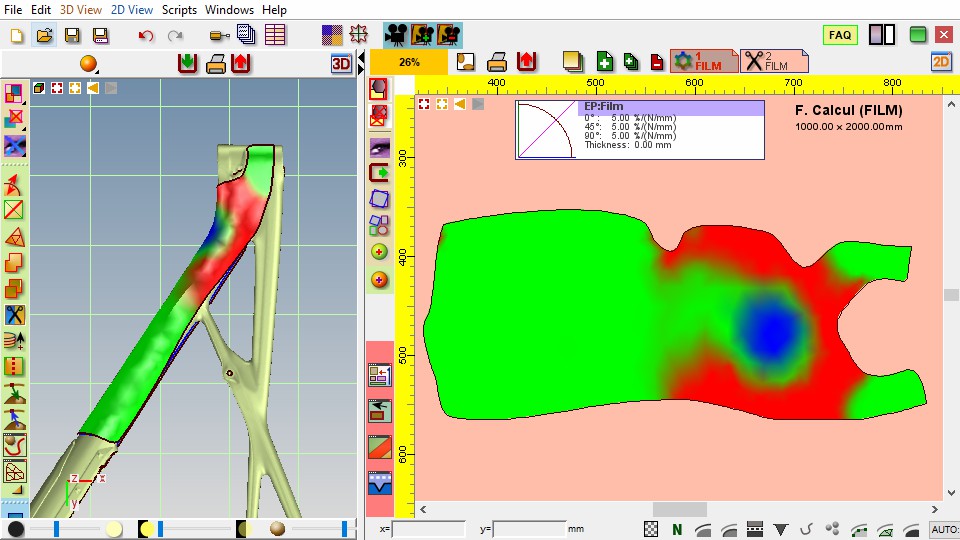

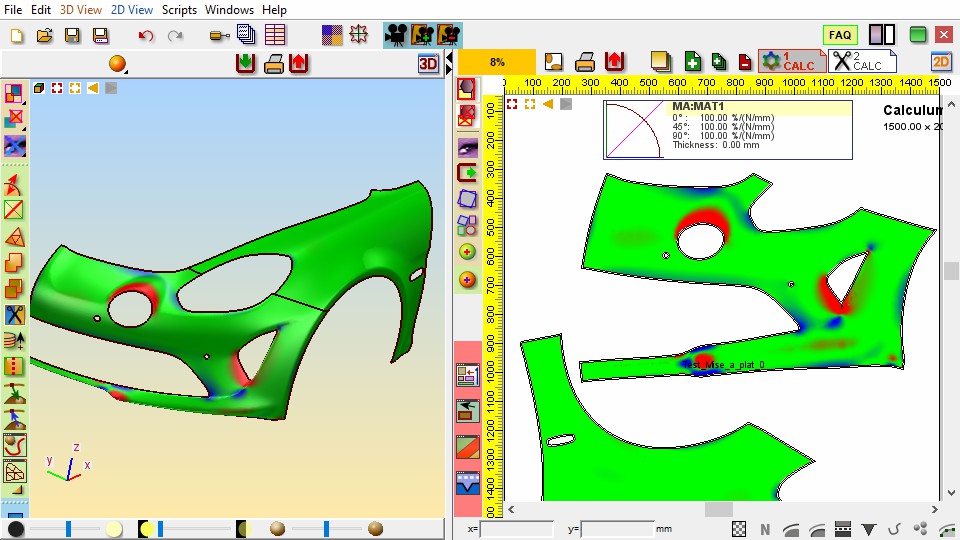

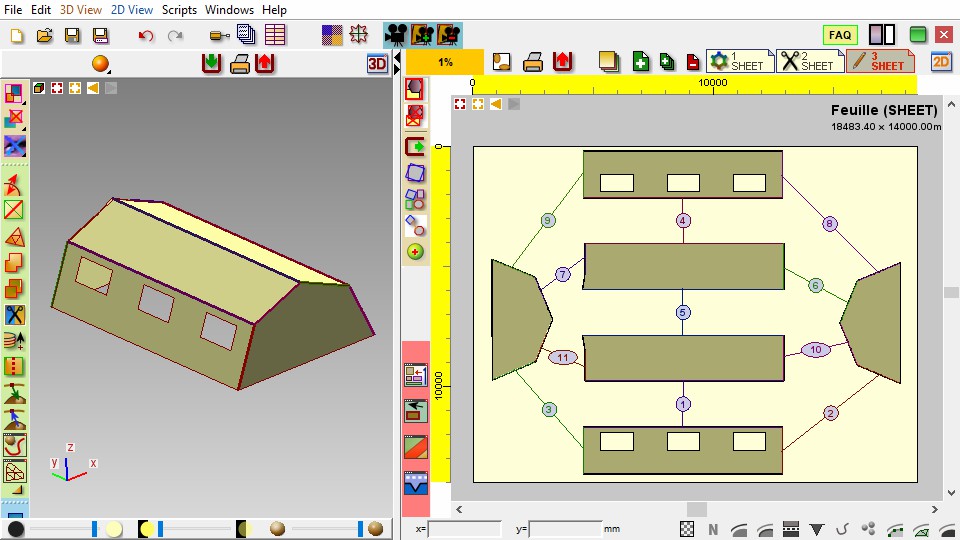

Composite materials

Wrapstyler's unfolding algorithm - the result of several decades of research and improvement - is very efficient. It allows to flatten surfaces composed of several hundreds of thousands of triangles. This is particularly well suited to the complexity of the surfaces to be made of composites.

In addition, a multi-ply function dedicated to composites makes it possible to calculate even more precisely the different folds of a part.

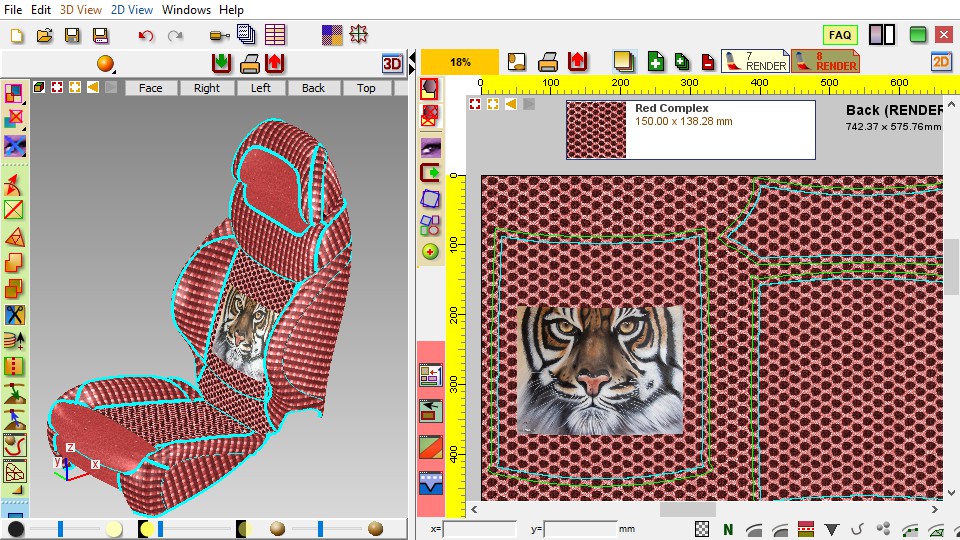

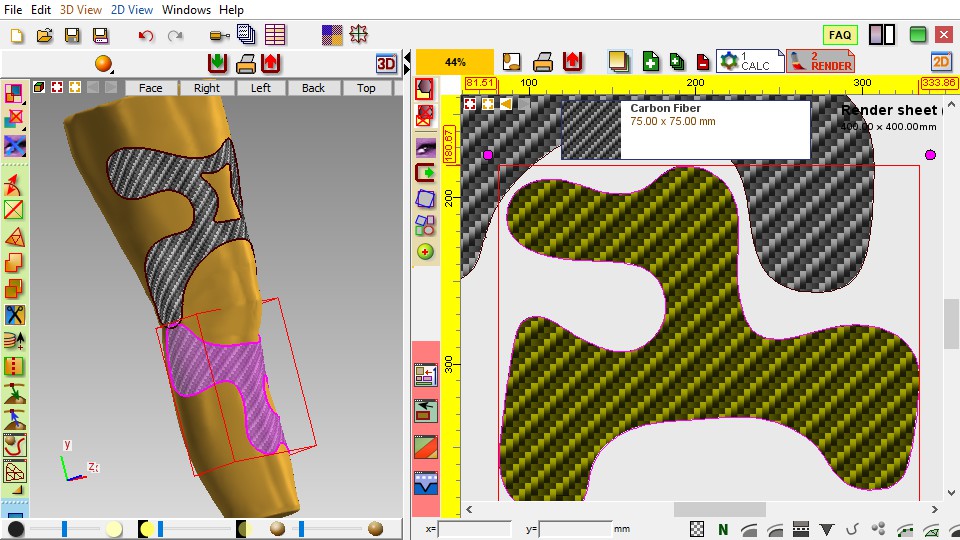

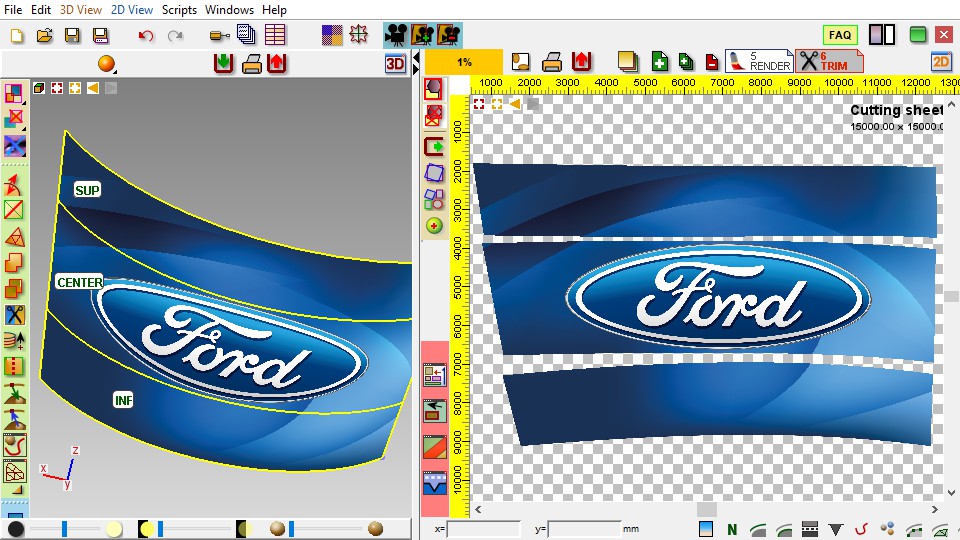

Texturing

Wrapstyler has always made it possible to simulate the texturing of 3D surfaces covered with 2D fabric in order to produce 3D images very easily but also to prepare data (OBJ, FBX, VRML, etc.) to produce hyper-realistic renderings using third-party software.

The latest versions of Wrapstyler go much further by adding multiple 3D texture projections but also by texturing the flaps allowing to obtain graphically perfect 3D assemblies whatever the assembly mode (sewing, welding, gluing, etc.) and the types of materials (fabric, PVC, film, etc.).

The graphic functions, used in very high resolution, combined with the new printers that allow printing on a wide range of materials, offer infinite creative possibilities.

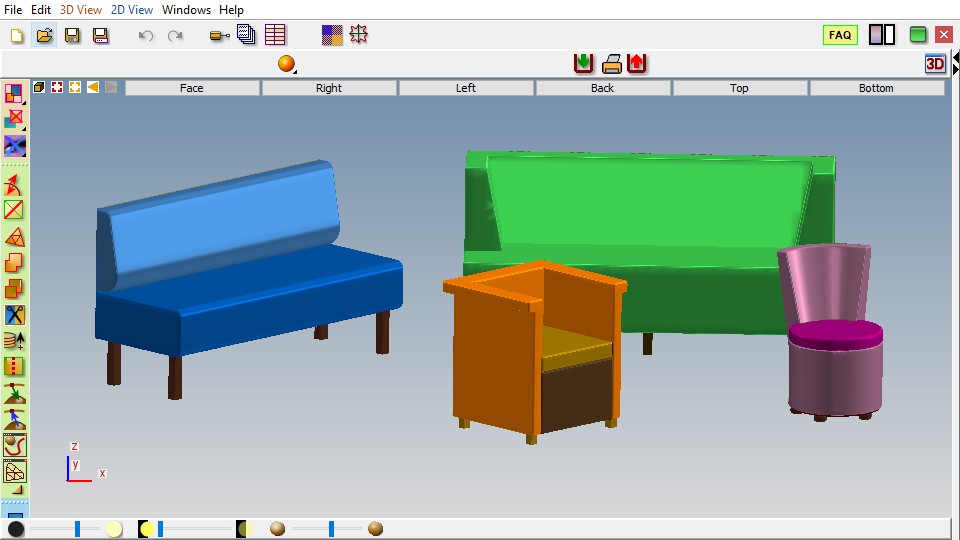

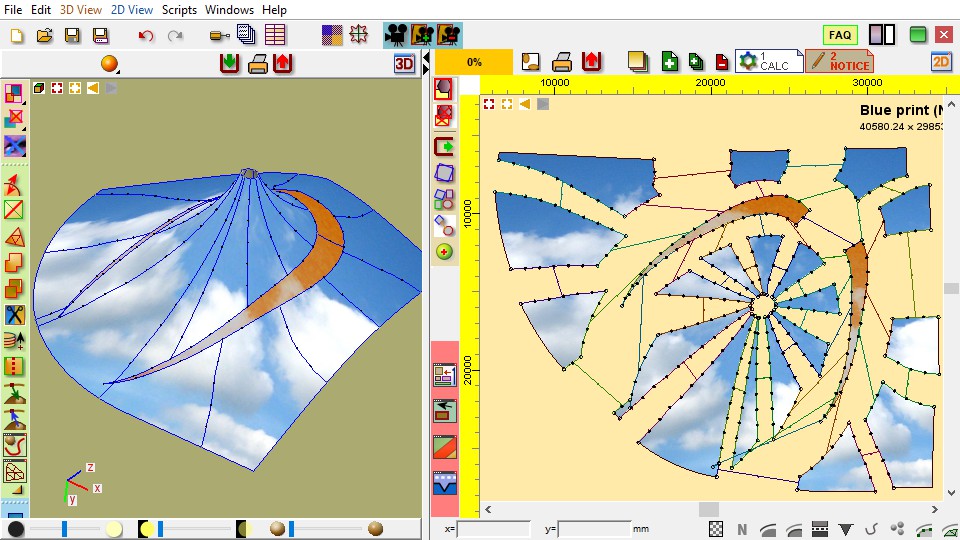

Others

Thanks to its generic calculation algorithms, its libraries of materials and customizable fabrics, Wrapstyler is adapted to many other applications, sometimes specific to each company.